Warehousing is preserving goods and materials in huge quantities in an orderly manners and making them available conveniently when needed. Warehouse management refers to maximize the efficiency and effectiveness of warehouse operations and regulation of goods including picking, packing, shipping, managing returns and inventory control.

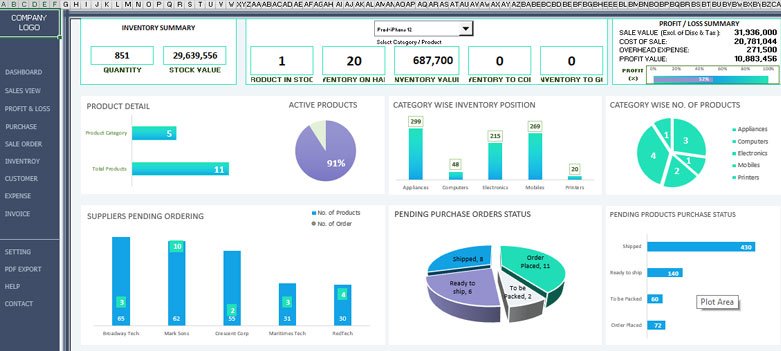

A Warehouse Inventory Management Excel is software that regulates and handles inventory and different operations in warehouse. Different WM systems offer different level of inventory capabilities of enterprises systems.

Introduction to Warehouse Inventory Management

Effective inventory management is crucial for maintaining optimal stock levels, minimizing costs, and ensuring timely product availability. Excel offers a flexible platform for managing warehouse inventory, allowing businesses to customize tracking, analysis, and reporting according to their specific needs.

Benefits of Using Excel for Warehouse Inventory

Excel’s cost efficiency, flexibility, and easy integration make it an attractive option for warehouse inventory management. Its customization capabilities allow for tailored inventory solutions, while its familiar interface reduces the learning curve for users.

What are the functions of warehouse management system?

Warehouse Inventory Management System provides multiples key features to assist you track the goods in current /existing storage activities and review the inventory control. Inventory management is nucleus of warehouse management including

- Products Quantity

- Products Value

- Location

- Products Turnover

- Track Purchases

- Inventory Movement

- Expanses

- Customers

- suppliers

To organize your warehouse, it is necessary to go through Warehouse Inventory Management Excel, so you can perform Stock tracking of your products, maintain the products, quickly supply the orders of customers, whole system can oversee with the help of these software that prevent loss and theft, workforce errors, easily handle and control bulk of goods and products as well as you can check the operator’s performance.

This software present storage facility and you can pick any item with no wastage of time from you warehouse. Its functionality is based on the following divisions:

- Inventory Management

- Work Execution

- Product Cost Analysis

- Reporting

Warehouse Inventory Management Excel provides you the facilities of tracking and maintaining the inventory bin location and get data from bin in warehouse,

- Inventory list shows items flagged in specific column that are ready for re-order.

- Inventory pick-list presents navigation links for inventory pick list and bin lookup worksheets to track each quantity SKU to fulfill orders.

- Bin Lookup this worksheet has a table that provides data for the inventory list and inventory pick list worksheets.

Different Warehouse Management System tools

Here there are shortlisted best warehouse management tools:

Key Features of Excel for Inventory Management

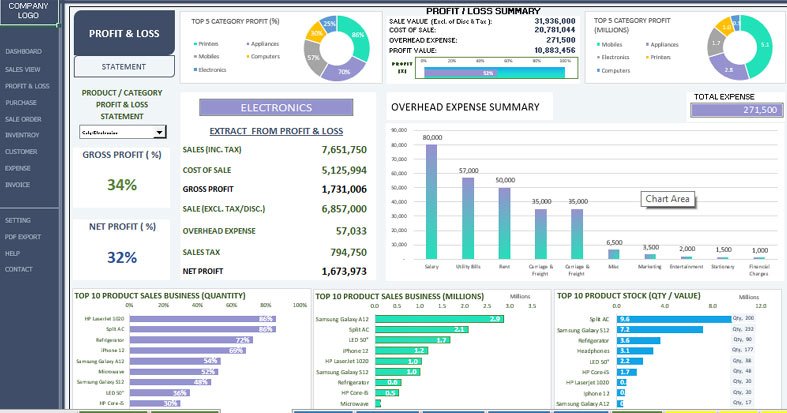

Excel’s robust formulas, functions, and data visualization tools facilitate efficient inventory management. Integration with other systems enhances Excel’s capabilities, allowing for seamless data flow across business processes.

- Data Entry and Organization

- Using Formulas for Inventory Management

- Conditional Formatting and Alerts

- Inventory Analysis and Reporting

- Advanced Excel Features for Warehouse Management

- Security and Data Protection

- Integrating Excel with Other Software

How you can manage Warehouse Inventory Management Excel?

To manufacture your warehouse, make sure that these processes are place in order to enhance the success and mobility of goods and services when needed.

Related Article: Procurement Management Plan Template

-

Designate a Warehouse-Keeper

First of all, it is better for warehouse to enlist a warehouse keeper with good experience and skills to run a warehouse in orderly manners and keep check on sophisticated technology to make warehouse operations more convenient and with ease of access.

He will supervise the usual activities of workers; keep often checks on your Warehouse Inventory Management Excel software to know how much goods/stock is available which item will be customer`s need for upcoming period and all that. His responsibility is to detect and sort out the problems or issues occurring in workforce.

To establish your workhouse without any flaws and run it in a smooth flow you must have a need of manager familiar with warehouse executions process, handle the unsupported things and have common sense and patience to deal and negotiate with transport companies, suppliers and clients.

-

Determine the Warehouse Layout

Set-up, location, shapes, sizes arrangements (protect the goods form sunlight, fire, rain, wind, dust and moisture) and areas are very points of every warehouse, but a structured and well formatted warehouse is necessary for every company to execute the effortless operations with no bother and no trouble.

Structuring the building of warehouse is very important because you have to be very careful about following

- Location of warehouse

- Its total proportional area

- Arrangements of goods

- Enough space for employees

- Movement in warehouse

- Internal and external environment of building.

Remember populate surrounding area is not suitable for warehousing it can creates reluctance for workers in quickly picking, packing, shipping and transfer products, causes limited production and overall profitability; warehouse should be located near the related areas like seaports, airports, railway stations and highways where goods can loaded and unpack easily.

Make sure layout of warehouse should be simple an

d secured with space utilization and enhance the functionality of operations and maximize the productivity and it is very good for an organization to locate the warehouse more than one place.

-

Establish A Workflow

Every organization wants to higher order rate and reduces cost and errors in warehouse functional processes. Workflow in warehousing determines that all operations are going through with basic steps toward next step and then final stag in a sequence and without identifying the problem. Warehouse Inventory Management Excel is one of the best solutions to all these issues.

It is responsibility of warehouse manager to keep an eye on workflow and make decisions accordingly and determine the new features of inventory management (explore the way in which new inventory received, tracked, load and shipped).

Workflow in warehouse inventory management accomplished operations in rapid speed, optimize warehouse activity, increase accuracy and efficiency, reduce the complexity of warehouse structure save time and also control the flow of materials (receipt, unit consolidation, binning, picking, packing and dispatching).

-

Utilize Warehouse Inventory Management Software

A warehouse inventory management software can helps you technically handle the tasks and update the existing stock automatically and management of warehouse. Though warehousing directly affects your chain supply management.

it is very time consuming to take over every minor detail of warehousing and inventory management by implementing management software you can easily oversee every matter of

- storage

- quantity

- stock

- payments

- Expenses

- wages

and other costs are also handled by using this software. Client details, supply quantities, demanding product, sufficient volume of goods are manipulated easily.

WIMS is very beneficial in reducing the risk of theft, mishandling, errors, cost reduction saving of human resources and time. You can find out which product is near to end, also how many days material is lying, optimize the capacity of storage and stock.

![]()

What are the benefits of warehouse Inventory Management System?

Warehouse Inventory Management Excel is demand in modern era of business, some major benefits are listed below

- Manage inventory in real time

- Track material and shipments

- Increase labor productivity and level of tracking

- Enhancing flexibility

- Greatly minimize the paperwork

- Reliable and valid inventory

- Enhance cycle counting

- Reduce overall cost

- Grow the supply chain

- Satisfy customers

- Utilization of storage unit in warehouse

- Monitors the stock movement

Best Practices for Excel Inventory Management

Maintaining an accurate and efficient inventory system in Excel requires adherence to best practices, including regular updates and staff training on inventory management techniques.

Conclusion: Optimizing Your Excel Inventory System

Leveraging Warehouse Inventory Management Excel offers numerous benefits, from cost savings to customization. By following the strategies outlined in this guide, businesses can maximize the efficiency and accuracy of their inventory management processes, ensuring a streamlined and effective operation.